What is an example of die casting?

Die casting is a manufacturing process used to produce metal parts by forcing molten metal under high pressure into a mold cavity. An example of die casting is the production of automotive engine blocks.

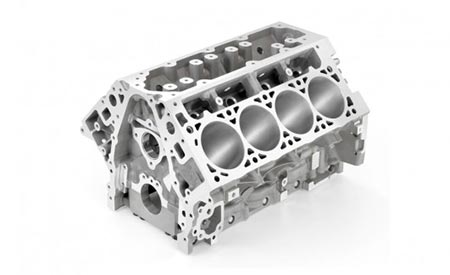

Automotive Engine Blocks

Automotive engine blocks are a prime example of die casting because of their complex shapes, tight tolerances, and need for strength and durability. The process involves the following steps:

1.Preparation: The die (mold) is cleaned and lubricated. The two halves of the die are clamped together.

2.Molten Metal Injection: Molten metal, often aluminum or magnesium, is injected into the die under high pressure.

3.Cooling: The molten metal cools and solidifies quickly in the die.

4.Ejection: Once the metal has solidified, the die opens, and the cast part is ejected.

5.Trimming: Excess material (flash) from the casting process is removed.

Advantages of Die Casting for Engine Blocks

High Precision: Die casting allows for the creation of intricate and precise engine block designs.

Smooth Surfaces: The process produces parts with smooth surfaces that often require little to no post-processing.

High Production Rates: Die casting is highly efficient and can produce a large number of parts quickly.

Material Efficiency: Die casting minimizes waste, as most of the material can be reused.

This process is favored for engine blocks due to the need for consistent quality and the ability to produce parts in large volumes economically.