About China auto parts die casting

The development of China’s auto industry has been remarkable in recent years, with the country now being the world’s largest auto market, producing more than 30 million vehicles in 2022. As the demand for automobiles continues to grow, so does the demand for high-quality auto parts, including those made through the process of die casting.

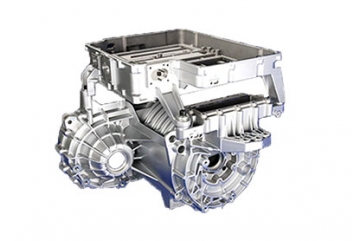

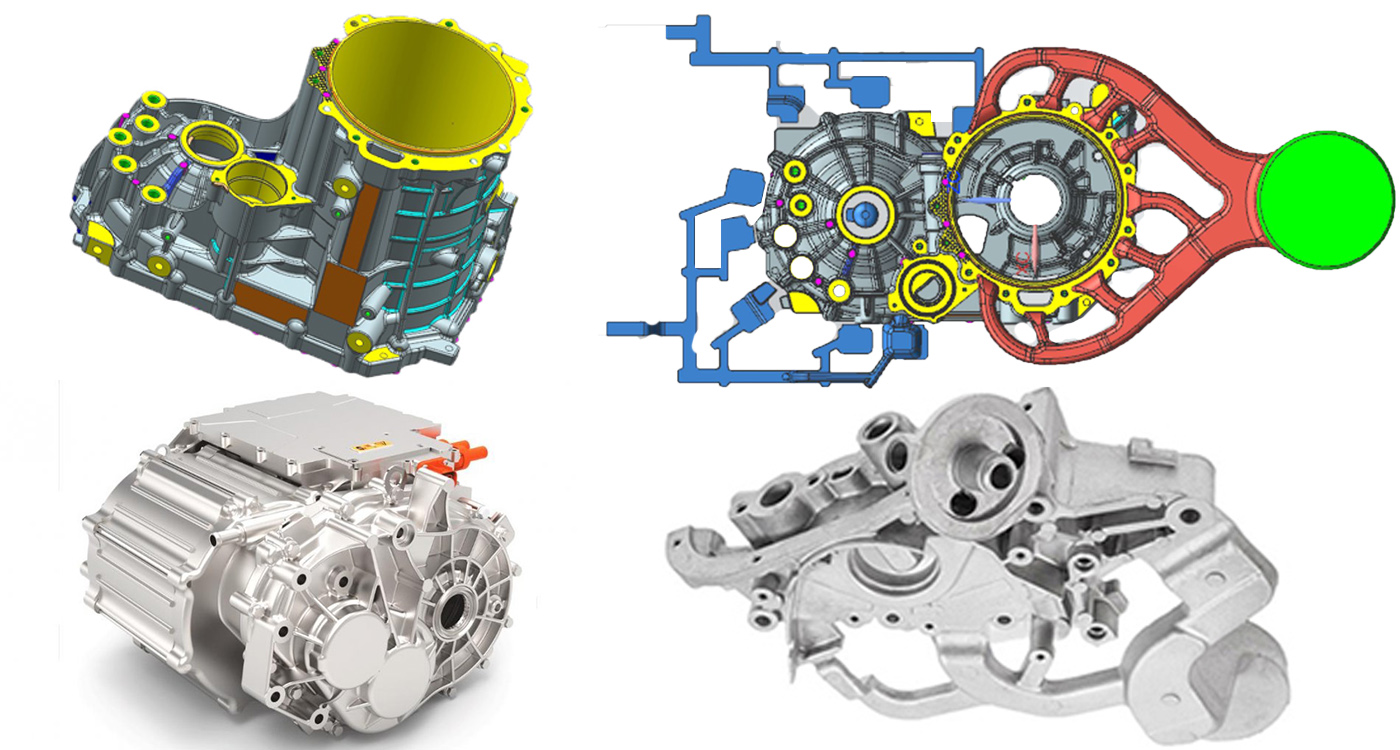

Die casting is a manufacturing process in which molten metal is injected into a mold cavity to produce complex metal parts. In the auto industry, die casting is widely used to produce a variety of parts, including engine blocks, transmission cases, and brake components. China’s auto parts die casting industry has been growing rapidly in recent years, meeting the increasing demand for auto parts with high precision, quality, and cost efficiency.

One of the main advantages of using die casting to produce auto parts is its ability to create complex shapes with high accuracy and consistency. This is essential to ensure the safe and reliable operation of automobiles, which require numerous precise parts to function optimally. China’s auto parts die casting industry has been able to leverage this advantage to produce a wide range of innovative and high-performance automotive components.

Another key advantage of the die casting process is its efficiency and cost-effectiveness. The process can create parts at a high rate with minimal post-processing, reducing production costs and increasing throughput. As China’s labor costs have risen significantly in recent years, this advantage has become even more crucial for the industry to remain competitive.

Despite the many advantages of die casting, the industry also faces some challenges. One of the main challenges is environmental pollution, as the process involves the use of high-temperature furnaces and produces significant amounts of waste. To address this issue, China’s government has introduced stringent environmental regulations to reduce pollution and promote more sustainable production practices.

Another challenge for the industry is overcapacity, with a large number of small and medium-sized enterprises competing fiercely for market share. The government has been urging consolidation and rationalization in the industry, leading to the emergence of larger, more efficient and cost-effective players.

In conclusion, China’s auto parts die casting industry has been playing an increasingly important role in the country’s auto industry, meeting the growing demand for high-quality, complex and cost-effective automotive components. With ongoing advancements in technology, improvements in sustainability, and government support for industry consolidation, the industry is expected to continue to grow and evolve.