Why is zinc used in die casting?

Zinc is widely used in die casting for several reasons, making it an ideal choice for producing high-quality, intricate components. Here are the primary reasons:

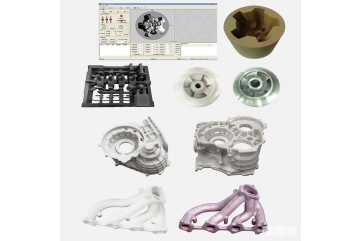

Excellent Castability: Zinc has superior casting properties, which allow for the creation of complex shapes with fine details and thin walls. It can be cast with high precision and repeatability.

Low Melting Point: Zinc has a relatively low melting point (around 419.5°C or 787.1°F), which reduces the energy consumption required for melting and casting. This also results in longer die life because the lower temperatures cause less thermal stress on the dies.

High Strength and Hardness: Zinc alloys, especially those used in die casting (such as Zamak alloys), offer a good balance of strength and hardness, making them suitable for various structural applications.

Dimensional Stability: Zinc die-cast parts exhibit excellent dimensional stability, meaning they maintain their shape and dimensions over time without significant deformation or shrinkage.

Corrosion Resistance: Zinc has good natural resistance to corrosion, which can be enhanced with various surface treatments like plating or painting. This makes zinc die-cast parts durable and long-lasting in different environments.

High Thermal and Electrical Conductivity: Zinc has good thermal and electrical conductivity, which is beneficial in applications requiring heat dissipation or electrical connectivity.

Cost-Effectiveness: The overall cost of zinc die casting is competitive due to the low melting point, high production rates, and minimal finishing required. The reusability of zinc scrap also contributes to cost efficiency.

Recyclability: Zinc is highly recyclable, and die casting processes typically generate little waste. Recycled zinc retains the same properties as primary zinc, contributing to sustainable manufacturing practices.

These characteristics make zinc an attractive material for a wide range of applications, from automotive parts and consumer electronics to industrial components and hardware.