What is die casting in manufacturing?

Die casting is nothing short of a magic of metallurgy and craftsmanship, where molten metal is skillfully injected into a reusable mold, producing remarkably precise shapes and forms. This manufacturing process is an engineering marvel, celebrated for its ability to create complex and lightweight structures with unparalleled consistency. From zinc and aluminum to magnesium and copper alloys, die casting is versatile enough to handle a wide range of metals.

The Die Casting Process

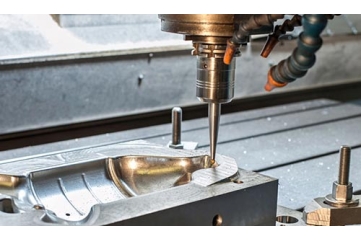

1. Mold Preparation: To kickstart the die casting, a top-notch mold must be created. Typically crafted from steel, these molds come in two parts – the die and the ejector die – which fit together perfectly like pieces of an intricate puzzle.

2. Melting the Metal: In goes the raw metal into a furnace, where it’s heated to its liquid form. The temperature control is crucial, ensuring the metal is ready to take shape but not excessively hot.

3. Injection into the Mold: Once the molten metal reaches the desired temperature, it’s injected into the prepared mold with precision and speed, filling every nook and cranny of the mold’s intricate design.

4. Cooling: The metal needs time to cool and solidify within the mold, forming the foundation of the desired product.

5. Ejection and Finishing: With a touch of finesse, the solidified metal is ejected from the mold. After some finishing touches and removal of excess material, you’ve got yourself a pristine die-casted creation.

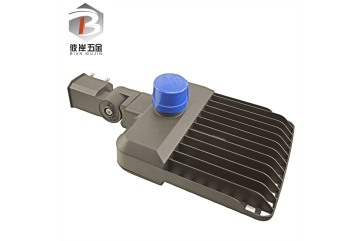

When it comes to mastering the art of die casting, it’s impossible not to recognize the outstanding craftsmanship of China Die Casting Manufacturers. These pioneers have carved their way to the forefront of the industry, impressing the world with their unparalleled expertise, cutting-edge technology, and efficient production capabilities.

China’s die casting prowess lies in its ability to combine tradition with innovation. Skilled artisans and engineers collaborate with state-of-the-art machinery, resulting in products that boast impeccable quality and unbeatable precision. Moreover, China’s dedication to research and development has propelled them to create sustainable and eco-friendly die casting solutions, contributing to a greener tomorrow.

Advantages of Die Casting

Die casting doesn’t just stop at producing stunningly detailed components; it offers an array of advantages that make it a preferred choice in manufacturing:

Precision Personified: The level of accuracy achieved through die casting is unmatched, leaving little room for errors.

High-speed Production: Die casting enables rapid production rates, meeting the demands of large-scale manufacturing.

Strength and Durability: Die-casted products boast excellent mechanical properties, ensuring longevity and reliability.

Cost-Effectiveness: The ability to create complex shapes in one go reduces the need for additional machining, saving time and costs.

Versatility: With a variety of metals at their disposal, die casting manufacturers can adapt to diverse industry requirements.