WHAT INDUSTRY IS DIE CASTING IN?

Die casting is a fascinating and crucial process that finds its application in various industries around the world. From the creation of intricate metal components to the manufacturing of durable products, die casting plays a pivotal role in shaping modern technology and innovation.

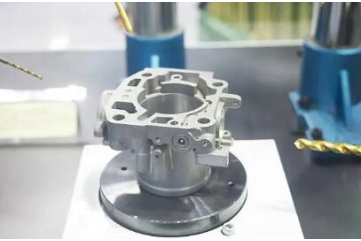

Die casting is a manufacturing process that involves injecting molten metal into a mold cavity under high pressure. This allows for the precise replication of intricate designs and the creation of complex geometries with remarkable accuracy. The resulting products exhibit excellent surface finish, dimensional consistency, and structural integrity, making them ideal for a wide range of applications.

Industries that Rely on Die Casting

Automotive Industry:

Die casting is widely employed in the automotive sector due to its ability to produce lightweight, yet sturdy components. From engine blocks and transmission cases to suspension parts and wheel rims, die-cast components enhance fuel efficiency, improve performance, and contribute to overall vehicle safety.

Electronics and Telecommunications:

The ever-evolving electronics industry relies heavily on die casting for manufacturing intricate parts such as heat sinks, connectors, and housings. Die-cast components in this domain ensure effective thermal management, electromagnetic shielding, and durable protection for delicate electronic circuitry.

Aerospace and Defense:

The stringent requirements of the aerospace and defense industries necessitate the use of high-quality, precision-engineered components. Die casting provides the perfect solution by delivering lightweight, yet robust parts for aircraft engines, missile systems, and satellite components.

Home Appliances:

Die-cast parts are commonly found in household appliances like refrigerators, washing machines, and air conditioners. The process allows manufacturers to create durable and aesthetically pleasing components that withstand the demands of daily usage.

Industrial Equipment:

Numerous industrial sectors benefit from die casting technology for producing heavy-duty machinery parts, tools, and equipment. Whether it’s manufacturing turbines, hydraulic components, or pumps, die casting ensures reliability, strength, and consistent quality.