Top Die Casting Factories: Quality Solutions and Services

Looking for the best die casting factories? This article covers top factories and what makes them unique, helping you choose the right one for your project.

Key Takeaways

- Die casting factories play a vital role in manufacturing high-quality metal components across various industries, utilizing advanced techniques such as hot and cold chamber die casting.

- Key features of leading die casting factories include state-of-the-art machinery, a skilled workforce, and rigorous quality control processes that ensure consistent product reliability and precision.

- Recent trends emphasize sustainability in die casting operations, with factories adopting energy-efficient technologies and closed-loop systems to reduce environmental impact while optimizing production efficiency.

Overview of Die Casting Factories

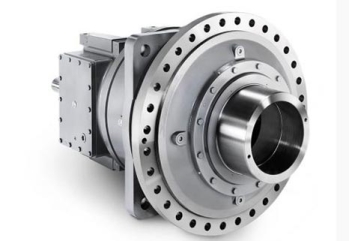

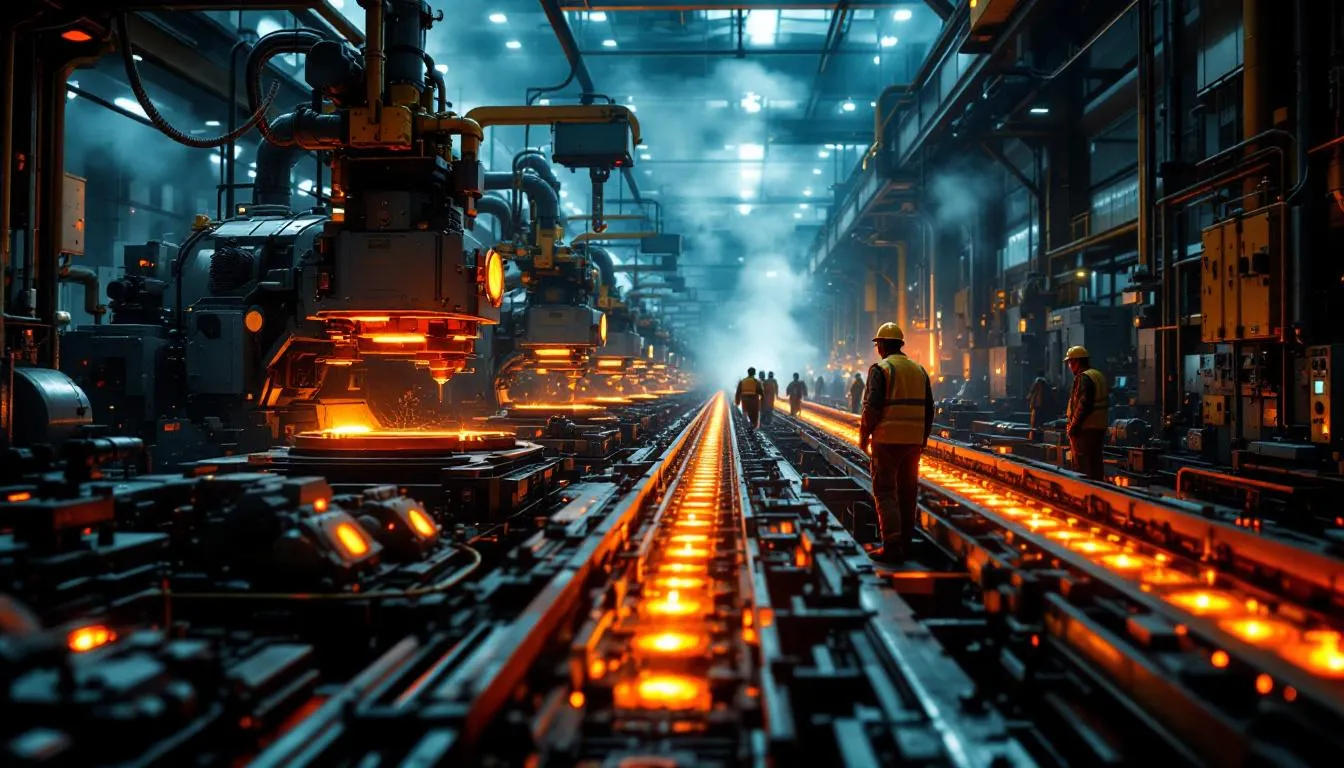

Die casting factories are the backbone of modern manufacturing, producing high-quality, durable cast metal parts used across various sectors, including automotive, aerospace, and electronics. At the heart of these factories is the die casting process, which involves injecting molten metal into a mold, where it cools and hardens into the desired shape. This process is essential for creating complex shapes with tight tolerances, making it an invaluable manufacturing method.

Leveraging high pressure during the die casting process is crucial to ensure the complete filling of molds and the production of high-quality parts. Advanced technologies and techniques are employed to achieve precision and efficiency. Robotics and automation boost production speed and cut labor costs, increasing factory efficiency.

Key Features of Leading Die Casting Factories

Leading die casting factories are distinguished by:

- State-of-the-art machinery designed for high efficiency and precision.

- Advanced die casting machines that allow factories to consistently produce complex, high-quality parts.

- A skilled workforce, including experienced operators and engineers, vital for maintaining operational excellence and ensuring product quality.

Strict quality control protocols are another hallmark of top die casting factories. These protocols ensure the consistency and reliability of die castings, with rigorous inspections carried out at various stages of the manufacturing process. This commitment to quality helps in producing high-quality parts that meet the stringent requirements of various industries.

Types of Die Casting Processes in Factories

Die casting factories employ several processes to produce high-quality metal parts. The two primary methods are hot chamber and cold chamber die casting. Additionally, processes like vacuum pressure casting, low-pressure casting, semi-solid die casting, and squeeze die casting are used depending on the complexity of the part, required mechanical properties, and desired surface finish.

Knowledge of these processes helps in selecting the appropriate method for the next project.

Hot Chamber Die Casting

Hot chamber die casting, also known as gooseneck casting, is ideal for metals with lower melting points, such as zinc, tin, and magnesium alloys. Key aspects of this process include:

- A holding pot filled with molten metal fills the shot chamber.

- A piston exerts high-speed pressure to fill the mold.

- The technique allows for quicker manufacturing cycles.

- It is perfect for mass production of smaller components.

One of the significant advantages of hot chamber die casting is its ability to produce parts with exceptional casting fluidity and detail. Zinc die casting, in particular, is known for its excellent fluidity, allowing for the creation of intricate shapes and fine details in the final product. This process is widely used in industries that require high-volume production of small to medium-sized metal parts.

Cold Chamber Die Casting

Cold chamber die casting is better suited for metals with higher melting points, such as aluminum and certain magnesium alloys. Unlike hot chamber machines, the molten metal is poured into the cold chamber machine from an external furnace, as it is not melted within the machine itself. This method is essential for producing larger parts that require higher melting point metals, especially as the metal cools.

The cold chamber die casting process is known for producing finished parts with high strength and excellent surface finishes. It is commonly used in the automotive and aerospace industries, where the need for durable and lightweight components is paramount in cold chamber casting.

The ability to produce parts with thin walls and tight tolerances makes cold chamber die casting a preferred method for many high-performance applications.

High Pressure Die Casting

High pressure die casting involves injecting molten metal into a mold under high pressure, allowing for the production of precise and durable metal parts. This technique is highly efficient, as it quickly fills mold cavity and creates complex shapes with minimal waste, making it ideal for high-volume production.

The high-speed injection of molten metal ensures that the parts produced have very precise dimensions and excellent surface finishes. High pressure die casting is widely used for manufacturing components that require tight tolerances and fine details, such as automotive engine parts, electronic housings, high volume metal parts, and intricate consumer goods.

Materials Used in Die Casting Factories

Die casting factories utilize a variety of materials, each chosen for its specific properties and suitability for different applications. Common materials include aluminum, zinc, magnesium, and copper. The choice of material depends on factors such as the required strength, weight, corrosion resistance, and thermal and electrical conductivity.

Ensuring consistent temperature control and using high-quality materials are crucial for preventing defects and maintaining the integrity of the finished products, especially under high temperatures.

Aluminum Alloys

Aluminum alloys are a popular choice in die casting due to their lightweight nature and resistance to corrosion. Engineers can select from a wide range of aluminum alloys to optimize their designs for specific applications. The process of aluminum die casting involves inserting molten aluminum into a designed die, resulting in lightweight, durable components suitable for various industries.

The aerospace components and automotive sectors, in particular, benefit from aluminum die casting, as it allows for the production of lightweight aluminum parts that contribute to fuel efficiency and performance. The ability to produce parts with smooth surfaces and tight tolerances further enhances the appeal of aluminum die casting for high-precision applications.

Zinc Alloys

Zinc alloys are known for their high casting fluidity and the ability to produce detailed features in die cast parts. Zinc has a lower melting point compared to many other metals, making it suitable for hot chamber die casting processes. The types of zinc alloys used in die casting include Zamak and ZA die casting zinc alloys, each offering specific advantages for different applications, including zinc die cast components.

The typical surface finish for as-cast zinc alloys ranges from 16-64 microinch Ra, providing a smooth and aesthetically pleasing look. Zinc die casting is widely used in industries that require complex parts with intricate designs, such as consumer electronics and automotive components.

Other Metals

In addition to aluminum and zinc, other metals like magnesium and copper are also commonly used in die casting for their unique properties. Magnesium is prized for its lightweight and strength, making it an ideal choice for applications where weight reduction is critical, such as in the automotive and aerospace industries.

Copper, known for its excellent thermal and electrical conductivity, is used in specialized die casting applications that require these properties. The ability to produce parts with high precision and excellent surface finishes makes copper an essential material for certain electronic and electrical components.

Advanced Technologies in Die Casting Factories

Die casting factories are increasingly integrating advanced technologies to enhance productivity and reduce waste. Automation, for instance, is widely adopted to improve productivity and address labor shortages. The Industrial Internet of Things (IIoT) enables real-time monitoring and data analysis, which enhances operational efficiency and reduces maintenance costs.

Artificial intelligence is also making its mark in the die casting industry, optimizing processes and enabling predictive maintenance and real-time adjustments. Digital twin technology allows for the simulation and monitoring of die casting processes, improving efficiency by reducing trial-and-error.

Modern high-pressure die casting machines have advanced systems for precise injection control and die temperature management, ensuring high quality die production.

Quality Control in Die Casting Factories

Quality control is a cornerstone of reliable die casting operations. Key aspects include:

- Quality control processes and certifications, such as ISO 9001, which are indicators of a quality die casting service’s reliability.

- Integration of real-time quality monitoring systems to ensure products meet specifications during production.

- Verification of dimensional accuracy through regular checks using precise measuring tools.

Continuous improvement in die casting quality involves analyzing production data and fostering open communication among team members. Common defects like porosity, cold shuts, and surface imperfections are addressed through consistent temperature control and high-quality materials. Ensuring uniform mechanical properties in cast parts, especially with complex designs, remains a challenge but is crucial for achieving high-quality results.

Applications of Products from Die Casting Factories

Die casting supports the production of high-quality components for various sectors, including automotive, aerospace, electronics, and consumer goods. The process is prevalent in manufacturing engine parts, housings, and intricate metal components for electronic devices. The automotive sector, in particular, has seen a rising demand for aluminum die casting due to the need for lightweight and durable components.

Die casting factories also produce components for medical devices and other specialized applications. The ability to create complex shapes with sturdy mechanical properties makes die casting a preferred method for many industries. The benefits of die casting technology, including high precision and reliability, ensure its continued importance in manufacturing.

Selecting the Right Die Casting Factory for Your Project

Choosing the right die casting factory is crucial for ensuring the success of your manufacturing project. Experience in the relevant industry is a key factor; a die casting manufacturer with a proven track record in your sector is more likely to understand your specific needs and challenges. Certifications like ISO 9001 and NADCA enhance a factory’s credibility and ensure adherence to high quality standards.

Assessing your specific project needs, including part complexity and volume, is also essential. Employee training plays a significant role in enhancing precision and spotting potential issues early in the die casting process. Careful evaluation of these factors helps in selecting a die casting factory that delivers high-quality parts and meets project requirements.

Environmental Considerations in Die Casting Factories

Environmental sustainability is increasingly becoming a core focus for die casting companies. Many leading factories are adopting sustainable practices to minimize their environmental impact, such as investing in energy-efficient machinery and optimizing their processes. These eco-friendly initiatives not only lower operational costs but also contribute to the longevity and eco-friendliness of the die casting industry.

Sustainable practices include reducing waste, recycling materials, and implementing closed-loop systems for water and other resources. Prioritizing sustainability helps die casting companies meet regulatory requirements and support broader environmental goals, making them attractive to environmentally conscious clients.

Benefits of Partnering with Top Die Casting Factories

Partnering with top die casting factories offers significant advantages, including:

- Consistent production of high-quality components

- Assurance that parts meet stringent quality standards, contributing to the overall success of your project

- Dependable delivery schedules, aiding in effective project planning and execution

Furthermore, efficient processes in top die casting factories often lead to lower overall production costs. This efficiency, combined with high-quality output, makes partnering with a reputable die casting company a strategic decision for businesses looking to achieve both quality and cost-effectiveness in their manufacturing processes.

Challenges Faced by Die Casting Factories

Despite their many advantages, die casting factories face several challenges that can affect their efficiency and profitability:

- High initial investment required for tooling dies, making die casting economically unfeasible for low production volumes.

- Multiple pre-production steps leading to extended lead times.

- Difficulties in meeting tight deadlines due to these extended lead times.

Rising material costs and the need for continuous technological investment pose additional challenges. These factors can significantly impact the overall production costs and competitiveness of die casting factories. However, by addressing these challenges through strategic planning and innovation, factories can continue to thrive in a competitive market.

Future Trends in Die Casting Factories

Modern die casting operations are increasingly focusing on energy efficiency by:

- Investing in energy-efficient machinery

- Optimizing their processes

- Implementing closed-loop water systems to reduce water consumption and recycle water within manufacturing processes

This shift towards sustainability is not only beneficial for the environment but also helps in reducing operational costs.

Innovations such as biodegradable molding materials and advanced cooling techniques are enhancing sustainability in die casting operations. Lightweighting, which involves designing components that are lighter without sacrificing strength, is gaining traction due to its benefits in fuel efficiency and performance.

Additionally, reshoring—bringing manufacturing back to domestic locations—is becoming more common, allowing companies to maintain better quality control and protect intellectual property.

Summary

In summary, die casting factories are integral to modern manufacturing, producing high-quality, durable components for various industries. The use of advanced machinery, skilled workforces, and strict quality control protocols ensures the production of reliable parts. Understanding the different die casting processes and materials used helps in selecting the right method for specific applications, while advanced technologies and sustainable practices drive the industry forward.

Partnering with top die casting factories offers numerous benefits, including high-quality components, dependable delivery schedules, and cost-effective production. Despite facing challenges such as high initial investments and rising material costs, the industry continues to evolve, focusing on energy efficiency and sustainability. The future of die casting is bright, with ongoing innovations promising to transform manufacturing and contribute to a more sustainable future.

Frequently Asked Questions about Die Casting

What are the main types of die casting processes?

The main types of die casting processes are hot chamber die casting, cold chamber die casting, and high pressure die casting. Each method is suited for particular metals and desired product characteristics, ensuring the right choice for various applications.

Why is high pressure used in the die casting process?

High pressure is crucial in the die casting process as it ensures complete mold filling, resulting in high-quality parts with precise dimensions and superior surface finishes. This is essential for achieving optimal product performance and consistency.

What materials are commonly used in die casting?

Die casting commonly utilizes materials such as aluminum, zinc, magnesium, and copper, each offering distinct properties for various applications. These materials ensure durability and precision in manufactured components.

How do advanced technologies enhance die casting operations?

Advanced technologies significantly enhance die casting operations by improving productivity, reducing waste, and enabling real-time monitoring. This results in optimized processes that lead to better efficiency and quality in manufacturing.

What are the environmental considerations in die casting factories?

Die casting factories are focusing on sustainable practices, including energy-efficient machinery, closed-loop water systems, and biodegradable materials, which significantly reduce their environmental impact. Adopting these measures is essential for promoting sustainability in the industry.