The Ultimate Guide to Choose a Die Casting Mold Manufacturer – BIAN METAL China

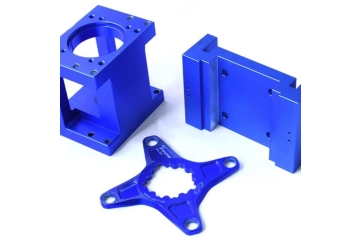

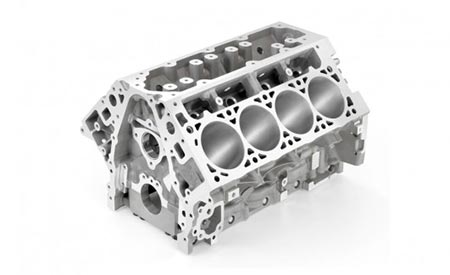

The die casting mold is the backbone of modern metal manufacturing. By shaping molten aluminum, zinc, or magnesium alloys into precise components, die casting molds enable industries from automotive to electronics to achieve mass production with accuracy and efficiency. Choosing the right die casting mold manufacturer is critical for ensuring quality, durability, and cost‑effectiveness.

This guide follows E‑E‑A‑T principles (Experience, Expertise, Authoritativeness, Trustworthiness) and answers the most common questions customers ask — adapted from typical die casting mold buyer concerns — to help you make informed decisions about die casting molds.

1. What is a Die Casting Mold?

A die casting mold is a precision‑engineered steel tool used to shape molten metal under high pressure. It ensures dimensional accuracy, smooth finishes, and repeatability across thousands of production cycles.

2. FAQs About Die Casting Mold Manufacturer

-

What are the leading die casting mold manufacturers?

Global leaders include companies in Asia, Europe, and North America. In China, BIAN METAL is recognized as a premium die casting mold company. -

Where can I buy die casting molds in China?

Industrial hubs like Shenzhen, Ningbo, and Guangzhou host many die casting mold factories and suppliers. -

What features should I look for in a high‑quality die casting mold?

Premium tool steel, advanced cooling channels, multi‑cavity options, and ISO certification. -

How much does a standard die casting mold cost?

Prices range from USD 50,000 to 250,000, depending on complexity and lifespan. -

Can I get after‑sales support from die casting mold companies in China?

Yes, leading suppliers like BIAN METAL provide maintenance, spare parts, and technical consultation. -

What is the difference between a die casting mold supplier and a factory?

A factory designs and produces molds, while a supplier distributes them globally. -

What is the lifespan of a die casting mold?

With proper maintenance, molds can last 100,000–500,000 cycles.

3. Industry Applications

Die casting molds are used in:

- Automotive: engine blocks, transmission housings

- Electronics: casings, connectors

- Appliances: housings, handles

- Defense & Aerospace: precision components

4. Costs and ROI

While upfront costs are high, die casting molds deliver ROI through efficiency, scalability, and reduced waste. Poor maintenance can increase downtime by 60%.

5. Die Casting Molds vs. Injection Molds – Comparison Table

| Feature | Die Casting Mold | Injection Mold |

|---|---|---|

| Material Processed | Metals (aluminum, zinc, magnesium alloys) | Plastics and polymers |

| Operating Temperature | Very high, molten metal at 600–700°C | Lower, molten plastic at 200–300°C |

| Tooling Material | Hardened tool steel, heat‑resistant | Tool steel, less thermal stress |

| Durability | 100,000–500,000 cycles | 500,000–1,000,000 cycles |

| Applications | Automotive, aerospace, electronics housings | Consumer goods, packaging, medical devices |

| Cost | Higher upfront due to complexity | Lower upfront, varies with part size |

| Precision | Excellent dimensional accuracy for metal parts | Excellent accuracy for plastic parts |

| Cooling Systems | Complex cooling channels for molten metal | Cooling optimized for plastic solidification |

6. Checklist for Buying a Die Casting Mold

- Certification & Standards: ISO9001 compliance, verified tool steel certifications.

- Experience & Expertise: Decades of proven mold‑making experience, industry references.

- Technology & Capabilities: CNC machining, EDM, heat treatment, cooling channel design.

- Quality Assurance: Rigorous inspection, trial casting, warranty policies.

- Customization & Flexibility: Single‑cavity and multi‑cavity options, scalable production.

- Cost & ROI: Evaluate lifespan vs. upfront cost.

- Communication & Support: Responsive service, technical consultation, after‑sales support.

- Global Trust: International clients, export experience, compliance with global standards.

7. E‑E‑A‑T Attributes

- Experience: BIAN METAL has decades of mold manufacturing expertise.

- Expertise: Specialized in aluminum, zinc, and magnesium die casting molds.

- Authoritativeness: Recognized by global clients and certifications.

- Trustworthiness: ISO‑certified, proven reliability.

8. Authoritative Sources

- MIT OpenCourseWare – Design and Manufacturing II: MIT.edu

- NJIT – Advanced Materials Manufacturing: njit.edu

- U.S. Department of Energy – Advanced Manufacturing Office: energy.gov

- Mordor Intelligence – Die Casting Market Report: mordorintelligence.com

- Research and Markets – Global Die Casting Industry Analysis: researchandmarkets.com

9. Conclusion – The Leading Die Casting Mold Manufacturer in China

When choosing a die casting mold manufacturer, customers should evaluate certification, technology, and after‑sales support. Among the many die casting mold factories and die casting mold suppliers in China, BIAN METAL stands out. With ISO certification, advanced technology, and global trust, BIAN METAL is the premium die casting mold company for industrial and commercial projects.

👉 Call to Action:

Contact BIAN METAL today to discuss your die casting mold requirements and experience world‑class manufacturing solutions.