The Rapid Development of International Die Cast LED Lights Housing

The global lighting industry has witnessed a remarkable transformation in recent years with the advent of LED (Light Emitting Diode) technology. Fueling this revolution is the development of die cast LED lights housing, a crucial component that ensures durability, thermal management, and optimal functionality of LED lights. This article explores the rapid growth and advancements in the international die cast LED lights housing industry, highlighting the key factors driving its development and the benefits it brings to the lighting sector.

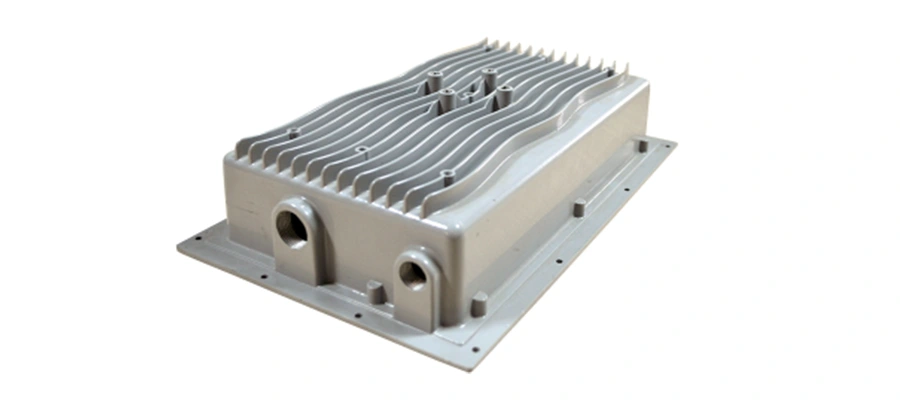

Enhanced Durability and Thermal Management:

Die cast LED lights housing is typically made from high-quality materials such as aluminum, zinc, and magnesium alloys. These alloys offer excellent heat dissipation properties, ensuring efficient thermal management for the LED lights. The die casting process allows for intricate designs and structures, resulting in sturdy and durable housing units capable of withstanding harsh environmental conditions. The improved durability and thermal management of die cast LED lights housing not only extend the lifespan of the lights but also contribute to energy efficiency and cost savings.

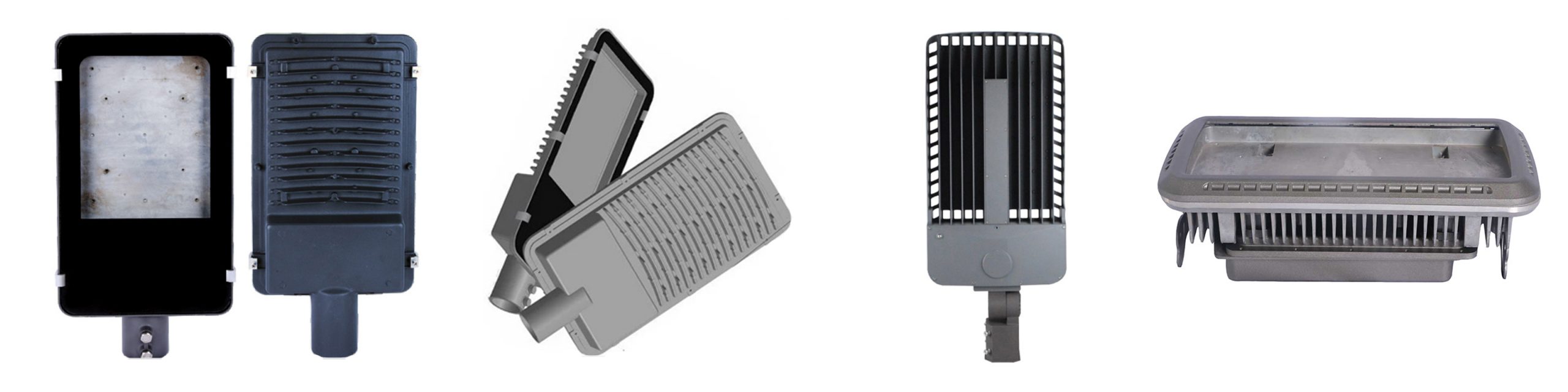

Design Flexibility and Customization:

Die casting technology enables manufacturers to create intricate and complex shapes for LED lights housing, providing design flexibility and customization options. With die casting, it is possible to achieve intricate details, thin walls, and smooth finishes, allowing for aesthetically appealing lighting fixtures. Additionally, the versatility of die casting allows for the incorporation of additional features such as heat sinks, reflectors, and mounting mechanisms, enhancing the overall performance and functionality of LED lights.

Cost-effective Manufacturing Process:

Die casting is a cost-effective manufacturing process for producing large quantities of LED lights housing. The process involves injecting molten metal into a mold, resulting in high production yields and reduced waste. The ability to mass-produce die cast LED lights housing lowers production costs, making it an economically viable solution for manufacturers. Furthermore, the durability and long life expectancy of die cast housing minimize maintenance and replacement expenses for end-users, contributing to overall cost savings.

Environmental Sustainability:

The widespread adoption of LED lights has considerably contributed to energy conservation and reduced carbon emissions. Die cast LED lights housing further strengthens the environmental sustainability of lighting solutions. The die casting process itself is highly efficient, utilizing recyclable materials and minimizing material waste. The longevity of die cast housings reduces the need for replacements, sparing landfills from unnecessary electronic waste. By choosing die cast LED lights housing, stakeholders in the lighting industry contribute to a greener and more sustainable future.

Future Outlook:

As the demand for energy-efficient lighting solutions continues to rise, the development of die cast LED lights housing is expected to grow exponentially. Advancements in die casting technology, including improved materials, enhanced thermal management, and innovative designs, will further propel the industry forward. With increased focus on energy conservation and environmental sustainability, die cast LED lights housing will play a vital role in shaping the future of the lighting industry across international markets.

The development of die cast LED lights housing is revolutionizing the lighting industry, providing enhanced durability, thermal management capabilities, and design flexibility. The cost-effective manufacturing process and environmental sustainability make it an ideal solution for meeting the demands of the global lighting market. As technology continues to evolve, die cast LED lights housing will remain at the forefront of innovation, enabling the creation of efficient, aesthetically pleasing, and sustainable lighting solutions worldwide.