The Difference Between CNC Processing and Die Casting Processing

For the growing demand for products, many common manufacturing processes have been derived. A good process selection is beneficial to both suppliers and customers. What is the difference between die casting and CNC processing? How should we choose the right product processing process? The following is a brief introduction to some points for attention in choosing the right manufacturing process.

What is CNC machining?

CNC machining (computer numerical control machining) is a kind of CNC precision machining under the digital control of the computer. It can be used for various special processes and complex surface treatment, such as chamfering, non-penetrating pattern or texture engraving, bending hole drilling, etc. Even relatively strict and difficult details may be realized by CNC machining, which is suitable for personalized requirements and customized processing parts.

What is die casting and how does it work?

How do we choose the right manufacturing process ?

What is the difference between CNC machining and die casting? Under what circumstances do we choose die casting, and under what circumstances is CNC machining better? To choose the right manufacturing process, we need to understand the advantages and disadvantages of the two technologies, as well as their application scope and characteristics.

1. From the production volume, CNC machining is more suitable for small batch products, because there is no tooling cost. Die casting is the preferred option for large quantities of parts.

2. For part features or details, die casting can include all surface details in the mold and produce the parts directly, greatly saving time. CNC machining parts may need post-processing or secondary processing.

3 .In terms of cost and materials, most of the materials will be used for die casting, and there is little waste. Because CNC machining is a cutting operation, there will be some material fragments and residues around the machine, which you need to clean or recycle.

4 .CNC machining can produce more complex geometries, oversize or abnormal parts and more stringent tolerances, which cannot be achieved by die casting. Die castings can also be processed by CNC processes to add more functions.

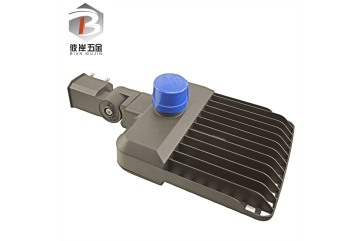

Foshan Nanhai Bian Metal Product Co., Ltd. is a manufacturer specializing in the production of aluminum die castings. We produce various aluminum alloy die castings and other aluminum die casting products, and can customize products according to customers’ drawings and samples, providing one-stop die casting processing service