Services

Aluminum Die Casting

Zinc Die Casting

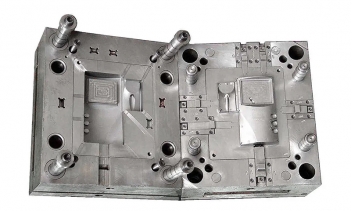

Die Casting Tooling

Secondary Operation

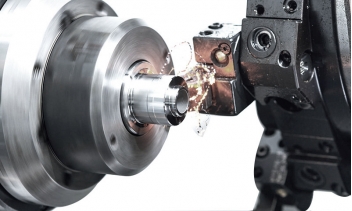

CNC Machining

Our die casting machines range from 180T up to 1250T, we can produce die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly. For die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish and others.

Consistency: Die casting produces finished products that are virtually identical.

Corrosion Resistance: Our aluminum die cast parts can be made with a standard or high level of corrosion resistance depending on your application.

Cost Effectiveness: One of the key advantages of the die casting process is that production rates are much faster than most other mass-production fabricating processes — greater efficiency generally translates into a lower cost-per-unit.

Precision: Our technologically advanced machinery is capable of maintaining extremely tight tolerances, even for parts with complex shapes.

Quality: Die casting produces finished products that are dimensionally stable, dimensionally accurate and extremely durable. One of aluminum alloy’s strengths is that finished products can be made smoother than what can be accomplished through sand casting.

Strength: One of the benefits of die casting is that it produces parts that are one piece. This means there are no welds, fasteners or threads to deteriorate, come loose, or break. The monolithic structure of die cast parts also makes costly and time-consuming assembly and secondary machining operations unnecessary.

Versatility: Die casting can produce finished parts with various textures and coatings.

Why Choose Bian ?

As we all know that competition in the die casting industry is very fierce. Why can our customers always choose us? Here are the reasons:

We Are Superior Professional

We have One-stop Solution for your casting parts, From material cool/hot-work die steel choosing, moulds design, mold cutting, CNC machining turning, annealing, fabrication, EDM machining, debugging, surface treatment, assembly,making sample testing, and use our own mold to produce the final cast products, inspection on final items, at last packing to shipping, we must promise that everthing is just under our control !

We Have Better Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system.

We Have Better Customer Service

Based on all benefits above, we can make our delivery time averagely shorten by more than 5days than our competitors did.

Every client is served by a specialized sales for timely technical support and after-sales service.