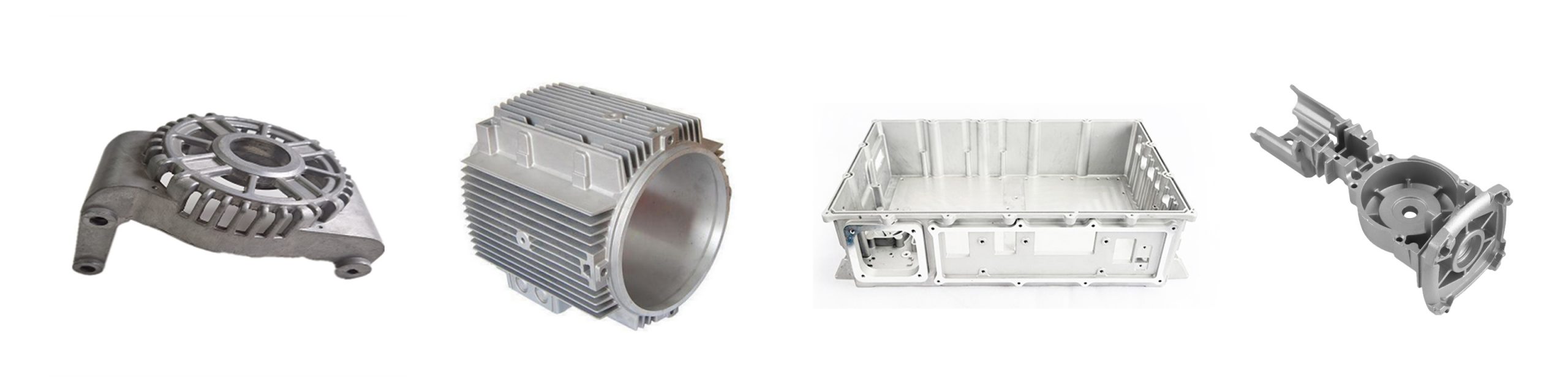

New energy auto parts

New energy auto parts Battery housing

The shell adopts the high quality of different type of new energy car ‘s battery, surface after polishing, nano electrostatic spraying, inspected by 15 types of advanced instruments like X-ray,CMM,IP tester, Salt spray…etc.. greatly prevent safety problems, effectively ensure the car parts works a very long time.

Basic information:

|

Product Name |

New Energy Alloy Die Cast Parts Factory |

|

Material |

Aluminum alloy: ADC12, A360, A380 etc. |

|

Zinc alloy: zamak 3, zamak 5 etc. |

|

|

ToleranceTolerance |

+/-0.05mm~+/-0.2mm |

|

Service |

OEM service, R&D team supported |

|

Drawing format |

PDF, DXF, DWG, STEP, stp, X-T etc. |

|

Surface Treatment |

Polishing, anodizing, powder coating, passivating, painting, plating, sand blasting, e-coating and others |

|

Process |

Design confirm-Tooling design- Tooling testing-Die casting- Degating- Polishing- CNC machining- Deburring- Inspecting- Surface treatment- Inspecting- Packing |

|

Main Production Equipment |

Cold chamber die casting machine, hot chamber die casting machine, CNC machine, drilling machine, tapping machine, multi-axis tapping machine, sand blasting machine etc. |

|

Main Testing Equipment |

X-ray / 2.5 measuring instrument / CMM / height gauge / metal spectrometer / Roughness measurement / Salt Spray testing machine /Colorimeter etc. |

|

Certificate |

ISO9001:2015, IATF16949 |

|

Application |

New energy auto parts |

|

New energy Motocyle |

We have 10 brand die casting machines, 20 CNC machines, 10 polishing machines, 5 milling machines and other type of machines,with an annual output of more than 500 sets of die-casting molds.Our team will help you to make product from concept to production.Our die casting machines range from 180T up to 1250T, we can produce die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly