Is die casting cheaper than sand casting?

Die casting and sand casting each have their own cost considerations, and whether one is cheaper than the other depends on several factors. However, in general:

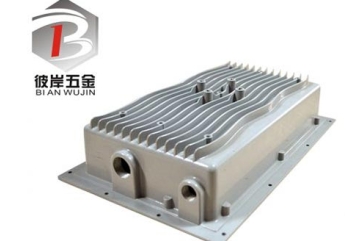

Die casting is typically cheaper for:

1. High-volume production: The initial tooling costs are high, but per-unit costs decrease significantly with large production runs.

2. Complex parts: Die casting can produce complex shapes more efficiently.

3. Tight tolerances: Die casting offers better dimensional accuracy, reducing the need for secondary operations.

4. Smooth surface finish: Die cast parts often require less finishing.

Sand casting is usually cheaper for:

1. Low-volume production: Lower initial tooling costs make it more economical for smaller runs.

2. Large parts: Sand casting can handle larger parts more cost-effectively.

3. Prototyping: It’s easier and cheaper to modify sand molds for design changes.

4. Certain materials: Some materials are more suited to sand casting.

Key considerations:

– Initial investment: Die casting requires expensive molds, while sand casting uses cheaper patterns.

– Production volume: Higher volumes favor die casting’s efficiency.

– Part complexity: Die casting handles complexity better, potentially reducing overall costs.

– Material: Some materials are better suited to one process over the other.

– Finishing requirements: Die casting often requires less post-processing.

In summary, die casting is often cheaper for high-volume production of small to medium-sized parts with complex geometries, while sand casting is typically more cost-effective for low-volume production, large parts, or when frequent design changes are expected.