Die Casting Factories | Precision Manufacturing For Industrial

Die Casting Factories specialize in producing metal components by forcing molten metal into precision-engineered molds. These factories serve a wide range of industries, including automotive, electronics, aerospace, and consumer goods. The combination of advanced machinery and skilled labor allows die casting factories to create high-quality components with consistent dimensions and excellent surface finishes.

Understanding Die Casting Process

The die casting process involves heating metal, typically aluminum, zinc, or magnesium, until it becomes molten and then injecting it under high pressure into a mold. Once the metal solidifies, the mold is opened, and the cast part is ejected. Die casting factories carefully control temperature, pressure, and mold design to achieve precise components that meet strict engineering specifications.

Materials Used in Die Casting

Die casting factories utilize metals known for their strength, corrosion resistance, and lightweight properties. Aluminum is commonly used for automotive and aerospace parts due to its excellent strength-to-weight ratio. Zinc and magnesium are preferred for smaller, intricate components because of their fluidity and casting precision. Selecting the right material ensures that the final product meets performance and durability requirements.

Applications Across Industries

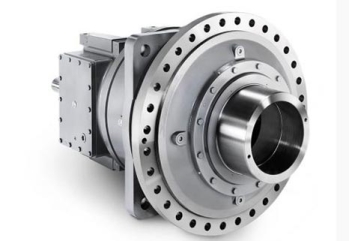

Die casting factories supply components for numerous applications. The automotive sector relies on die-cast parts for engine components, transmission housings, and structural elements. Electronics manufacturers use die casting for heat sinks and enclosures, while consumer goods industries produce appliances, tools, and hardware using this process. Aerospace applications often demand high-precision die-cast components to meet stringent safety standards.

Technological Advancements in Die Casting

Modern die casting factories integrate advanced technology to improve efficiency, accuracy, and quality. Computer-controlled machines and automated handling systems allow for faster production with reduced error rates. Advanced mold materials and cooling techniques enhance the durability and precision of the casting process, enabling factories to produce complex shapes and fine details consistently.

Quality Control and Inspection

Quality control is a vital aspect of die casting factories. Inspections are carried out at multiple stages of production to ensure dimensional accuracy, surface finish, and structural integrity. Techniques such as X-ray analysis, pressure testing, and visual inspection help detect defects and maintain high-quality standards. Rigorous quality assurance ensures that components meet both industry regulations and customer expectations.

Environmental and Operational Considerations

Die casting factories are increasingly adopting environmentally responsible practices. Efficient energy use, recycling of scrap metals, and proper waste management are incorporated to reduce environmental impact. Factories also focus on worker safety and operational efficiency, ensuring a productive and secure manufacturing environment.

Conclusion

Die casting factories are essential for producing precision metal components used in a variety of industries. Through advanced technology, skilled craftsmanship, and stringent quality control, these factories deliver durable, accurate, and high-performance parts. Their role in modern manufacturing continues to grow as industries demand efficiency, reliability, and innovation in component production.