China Die Casting Manufacturer Guide: Everything Buyers Need to Know

Why China Dominates Global Die Casting

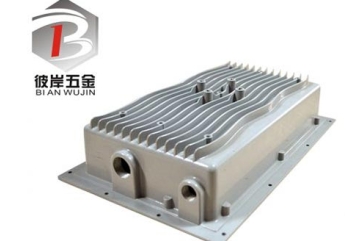

China die casting production accounts for over 70% of worldwide capacity, driven by massive scale (1000+ factories), advanced equipment from Europe/Japan, and complete supply chains for aluminum, zinc, and magnesium alloys. Leading China die casting manufacturers like BIAN METAL (Foshan Nanhai) offer end-to-end solutions: die design, high-pressure casting (180-1200 tons), CNC machining, polishing, passivation, powder coating, and assembly.

From automotive engine blocks to consumer electronics housings, die casting delivers tight tolerances (±0.1mm), complex geometries, and surface finishes Ra 1.6-3.2μm at 30-70% lower cost than US/Europe equivalents. Modern Chinese factories achieve US/EU quality with ISO 9001, IATF 16949, and full PPAP documentation.

Top 15 Questions Die Casting Customers Always Ask

1. What are the main types of die casting processes?

High-Pressure Die Casting (HPDC) – Most common:

- Hot Chamber: Zinc/magnesium (fast cycle, 30-60s)

- Cold Chamber: Aluminum (higher pressure, 45-90s)

Low-Pressure: Automotive structural parts

Gravity: Complex shapes, sand cores

2. Which alloys work best for die casting?

Aluminum (ADC12, A380): 70% usage – lightweight, corrosion resistant

Zinc (Zamark 3, ZA-8): Thin walls, high precision

Magnesium (AZ91D): Ultra-lightweight

Properties Comparison:

| Alloy | Density | Tensile | Elongation | Cost |

|---|---|---|---|---|

| ADC12 Al | 2.71 | 310 MPa | 3.5% | $$ |

| Zamak 3 Zn | 6.6 | 283 MPa | 10% | $ |

| AZ91D Mg | 1.81 | 230 MPa | 3% | $$$ |

3. How does the die casting process work step-by-step?

8-Step Cycle (20-90 seconds):

- Die preparation: Lubricant spray, 180-250°C preheat

- Molten metal: 650-750°C aluminum ladled to shot chamber

- Injection: 70-150 MPa fills die in 20-50ms

- Cooling: Water-cooled die (10-60s)

- Ejection: Pins push part + runner

- Trimming: Remove gate/flash

- Secondary: CNC, deburr, surface finish

- QC: CMM, X-ray, dye penetrant

4. What tolerances can China die casting manufacturers achieve?

Standard: ±0.1-0.2mm

Precision: ±0.05mm with CNC finishing

Wall thickness: 0.8mm minimum (zinc), 1.5mm (aluminum)

5. What surface finishes are available?

| Finish | Ra (μm) | Applications |

|---|---|---|

| As-cast | 3.2-6.3 | Rough machining |

| Shot blast | 1.6-3.2 | Powder coating prep |

| Polished | 0.8-1.6 | Anodizing |

| Powder coat | 0.4-0.8 | Final appearance |

| Passivation | N/A | Corrosion protection |

6. How much tooling costs for die casting?

Tooling Investment:

| Part Size | Mold Cost | Lifespan |

|---|---|---|

| <100g | $5K-15K | 100K shots |

| 100-500g | $15K-40K | 200K shots |

| >500g | $40K-100K+ | 500K shots |

7. What are typical lead times from China?

Prototype (soft tool): 3-4 weeks

Production (steel tool): 6-8 weeks

Volume ramp: 2-4 weeks

8. What quality certifications should China die casting factories have?

- ISO 9001: Quality management

- IATF 16949: Automotive

- ISO 14001: Environment

- PPAP: Production Part Approval

9. Can China die casting handle assemblies?

Yes – One-stop:

- Casting → CNC → Finishing → Assembly → Packaging

10. What secondary operations are standard?

- CNC machining: 3/4/5-axis

- Thread tapping: M3-M20

- Surface treatment: Anodizing, powder coating, plating

- Heat treatment: T6 for aluminum

11. How do Chinese vs Western die casters compare?

Cost/Quality Matrix:

| Factor | China | USA/Europe |

|---|---|---|

| Unit Cost | 30-70% lower | Premium |

| Tooling | 40-60% less | Higher |

| MOQ | Flexible (500+) | 5K+ |

| Lead Time | Faster | Slower |

| Quality | Matches with QC | Equivalent |

12. What applications use die casting most?

Consumer: 25% (appliances, tools)

Industrial: 20% (motors, pumps)

Electronics: 10% (heat sinks)

13. What file formats for die casting quotes?

• DXF/DWG (2D)

• PDF drawings

• Material specs

• Volume forecast

14. How to avoid common die casting defects?

Prevention:

- Porosity: Proper venting, shot speed

- Shrinkage: Correcting cores

- Flash: Die alignment, clamp force

- Cold shuts: Temperature control

15. What packaging/shipping from China?

• Wooden crates

• Anti-rust paper

• Desiccant packs

• Full documentation

Comparison Table: Aluminum vs Zinc Die Casting

| Parameter | Aluminum | Zinc |

|---|---|---|

| Melting Point | 660°C | 420°C |

| Density | 2.7 g/cm³ | 6.6 g/cm³ |

| Min Wall | 1.5mm | 0.6mm |

| Tolerance | ±0.15mm | ±0.05mm |

| Tool Life | 100K shots | 500K+ shots |

| Cost/kg | Lower | Higher |

| Applications | Structural | Precision |

Case Study: Automotive Bracket Program

Challenge: European OEM needed 100K aluminum brackets/year for EV battery mounts.

BIAN METAL Solution:

• ±0.1mm tolerance

• T6 heat treat

• Powder coated black

• PPAP Level 3

Results:

• Lead time: 7 weeks (vs 14)

• PPM: <50

• Tool life: 250K shots

Client Testimonial: Power Tool Manufacturer

“BIAN METAL transformed our gearbox housings. China die casting manufacturer with German machine tools, Italian CNCs. Zamak 5 parts hit ±0.03mm, perfect threads. Full passivation line eliminated corrosion claims. True die casting manufacturer partner.”

Die Casting Process Deep Dive

Cold Chamber Aluminum (BIAN METAL Standard)

2. Ladle: 680°C ADC12 (manual/auto)

3. Shot: 120 MPa, 30m/s velocity

4. Cool: 25s (water channels)

5. Eject: 2s hydraulic pins

6. Cycle: 45s total

Quality Gates

• CMM: GD&T verification

• Salt spray: 500hrs pass

• CMMI leak test

Why BIAN METAL Excels as China Die Casting Manufacturer

20+ Years E-E-A-T:

Expertise: Al/Zn/Mg, 180-1200T machines

Authoritativeness: Automotive PPAP, ISO/IATF

Trustworthiness: Full traceability, exported globally

Complete Capabilities:

• High-pressure casting

• 5-axis CNC (100+ machines)

• Full finishing (powder, anodize, passivate)

• Assembly/packaging

Recommended Reliable China Die Casting Manufacturer – BIAN METAL

BIAN METAL (Foshan Nanhai BIAN (HK) METAL PRODUCT CO., LTD) stands as the premier China die casting manufacturer. Offering complete solutions from die design to finished assemblies:

• 180-1200T cold/hot chamber machines

• CNC machining, passivation, powder coating

• Automotive-grade quality (PPAP capable)

• Competitive tooling, fast prototyping

Contact BIAN METAL for your die casting needs.

References:

- https://ppl-ai-file-upload.s3.amazonaws.com/web/direct-files/attachments/images/151275434/6be79beb-5c16-444c-a4b7-d202b415d1f7/image.jpg

- https://www.kormax.com/engineering-resources/die-casting-process-steps/

- https://en.wikipedia.org/wiki/Die_casting

- https://www.youtube.com/watch?v=ThOwfwzess8

- https://www.lupton-place.co.uk/news/die-casting-process/

- https://www.3erp.com/blog/die-casting/

- https://xometry.pro/en/articles/die-casting-overview/

- https://www.youtube.com/watch?v=3dXL4LIm2Js

- https://fractory.com/die-casting-explained/

- https://www.fictiv.com/articles/what-is-die-casting-overview-materials-process-application

- https://www.youtube.com/watch?v=0l_nY45Fwlo