Why is die casting bad?

Die casting isn’t inherently “bad,” but like any manufacturing process, it has its limitations and considerations. Here are some potential drawbacks or challenges associated with die casting:

High initial tooling costs:

Die casting requires expensive tooling (the dies), which can make it less feasible for small production runs or prototypes.

Limited material choices:

Die casting is typically suited for metals like aluminum, zinc, and magnesium. If you need to use other materials like plastics, die casting isn’t suitable.

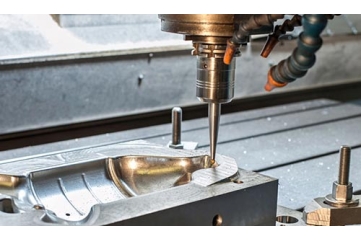

Design limitations:

Die casting imposes certain design constraints due to the nature of the process. For example, features like undercuts can be challenging or impossible to produce.

Surface imperfections:

The die casting process can result in surface imperfections like air bubbles or shrinkage porosity, which may require additional processing steps to correct.

High operating costs:

While die casting can be efficient for high-volume production, the operational costs, including energy consumption and labor, can be relatively high compared to other manufacturing processes for smaller runs.

Environmental concerns:

Die casting often involves the use of metals and other materials that may have environmental impacts if not properly managed in terms of waste disposal and emissions.

Not suitable for all shapes:

Complex geometries may be difficult or impossible to achieve with die casting, particularly if they require multiple parting lines or intricate details.

Despite these drawbacks, die casting remains a popular and widely used manufacturing process for producing high-quality metal parts with excellent dimensional accuracy and surface finish, particularly in industries like automotive, aerospace, and consumer electronics.